The right solution for every aspect of your project

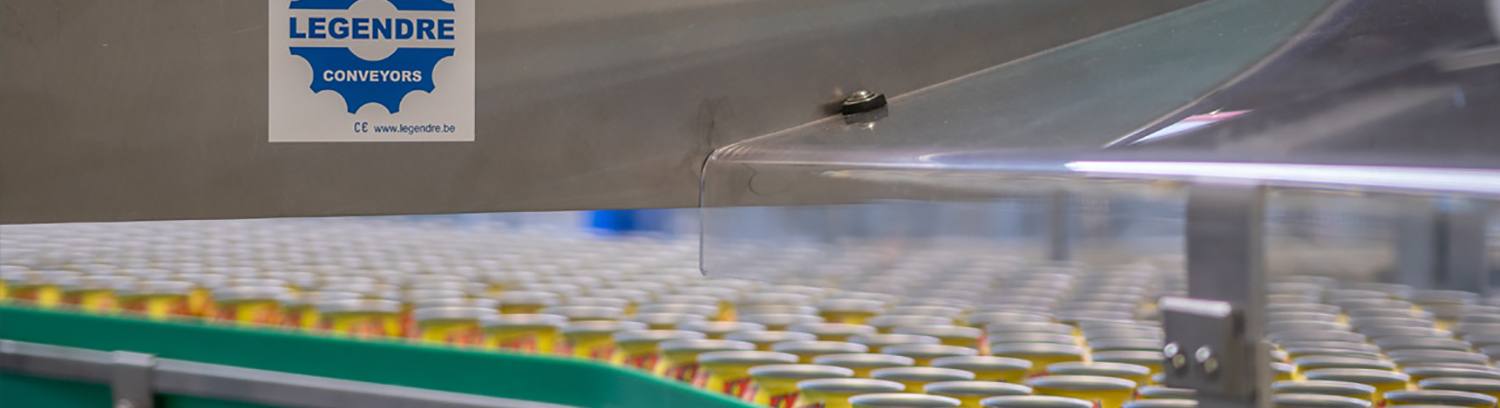

Do you produce beer, soft drinks, water, wine, dairy products, edible oil, food in cans or jars or lubricants? And do you supply these products in bottles, cans, jars, cylinders, barrels, boxes, containers or crates? Is your packaging made of glass, PET, PEHD, aluminium, cardboard, plastic, stretch wrap or a different material? Legendre is the right partner for your company!

We build completely new lines, adapt existing lines to new packaging and upgrade lines to ensure better line efficiency, whether close to home or on the other side of the world. Give us a call and together we’ll determine the best possible solution.

New projects

- New production Line design and balancing

- Primary and secondary packaging conveyors

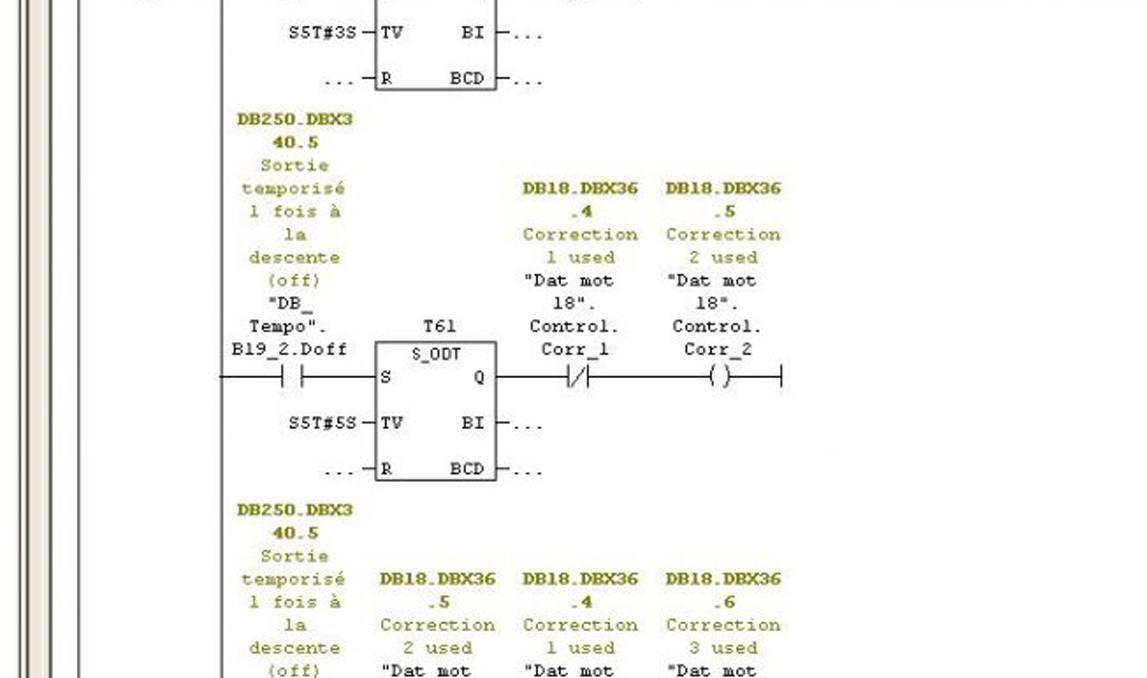

- Automation and line controls, including machines interfacing

- Integration of machines, Turnkey scope

Line adaptations

- Insertion of accumulation systems FIFO and FILO

- Adaptations for new or replacement machines

- Relocation projects

- Creation of new production configurations

Upgrades / Retrofits

- Speed enhancements, de-bottlenecking

- OEE/ROI, Improvements and consultancy

- New bottle and/or pack formats

- Automation & Control upgrades

Services & Contracts

- Spare parts, sourcing and manufacturing

- Field services, hourly rates or all-in amount

- Maintenance & Training, audits and execution

- Frame contracts or call-off agreements

![]() Engineering

Engineering

Custom concept for optimal flow

What’s your challenge? This is where it all begins. Together with you, we examine all the options and possibilities. We then develop an initial concept layout, taking into account the nature of your products, processes and available space and with a clear focus on your input and ideas. Thanks to our extensive knowledge, this results in a strong design for new lines or adaptations and upgrades to existing lines. The smarter the conveyor layout, the fewer vulnerable points in the line. This approach creates a healthy foundation for optimal efficiency. We then construct the conveyors in our workshop and prepare them for on-site installation.

![]() Efficiency Increase

Efficiency Increase

High line efficiency: maximum utilisation of production capacity

![]() Integration

Integration

Independent selection and integration of the best units in the market

You, in turn, enjoy the freedom of selecting the best units for every line component. We programme the integration of the machines with the conveyors in open and accessible software, giving you complete line management control.

![]() Installation and start-up

Installation and start-up

In compliance with the agreed delivery date

Our in-house technicians install your production line at your location or, alternatively, we assist your teams with the installation process. You decide. Our in-house programmers then start up your new line. They ensure correct communication between your machines and optimal speed regulation of all machines and conveyors. We take a flexible approach, consider your current production schedule as much as possible and limit the downtime of your units to a minimum. Tight deadlines are dealt with internally, so we finish on time.

The combination of our expertise, in-house manufacturing and in-house programming results in the fast implementation of our custom solutions. Your installation is fully operational within the shortest possible time frame.

![]() Support

Support

From troubleshooting to complete overhaul

Experiencing problems with your line? We can either visit your facility for an inspection or resolve the problem by way of remote troubleshooting via an online connection. Either way, we are ready to provide support in order to keep the downtime of your lines to a minimum. We also supply replacement parts at short notice from our own workshop or via our network of major brand suppliers.

Has your line reached the point of requiring a complete overhaul or maintenance? Again, we are here to help and can carry out a complete analysis of the line. Our team will audit your line and work with you to prepare a list of required replacement parts before carrying out the necessary maintenance work and installing the new parts. Your line will then be ready for efficient production within no time.

![]() Product range

Product range

Conveyors, accumulation systems, inliners, switches and more

We build all conveyors for both primary and secondary packaging in our own workshop using components of only the very best quality. Our experience and expertise is integrated into our mechanical designs for maximum reliability and a long service life, resulting in a high return on investment.